CAPABILITIES

Our continuous investment strategies provide you with the support and service you deserve.

We leverage our progressive skillset, experience, and cutting edge technology to provide a dynamic range of key industry support. With a variety of offerings in diverse industries, Jerl Machine is your one-stop shop for trusted service.

Check out our capabilities list below

Please click here for a printable capabilities page

Make sure to check back often and follow our socials to stay up to date with company news, equipment updates, and employee appreciation.

- 5-AXIS MACHINING CENTERS

- Wire EDM

- CNC HORIZONTAL MACHINING CENTERS – HMC

- CNC VERTICAL MACHINING CENTERS – VMC

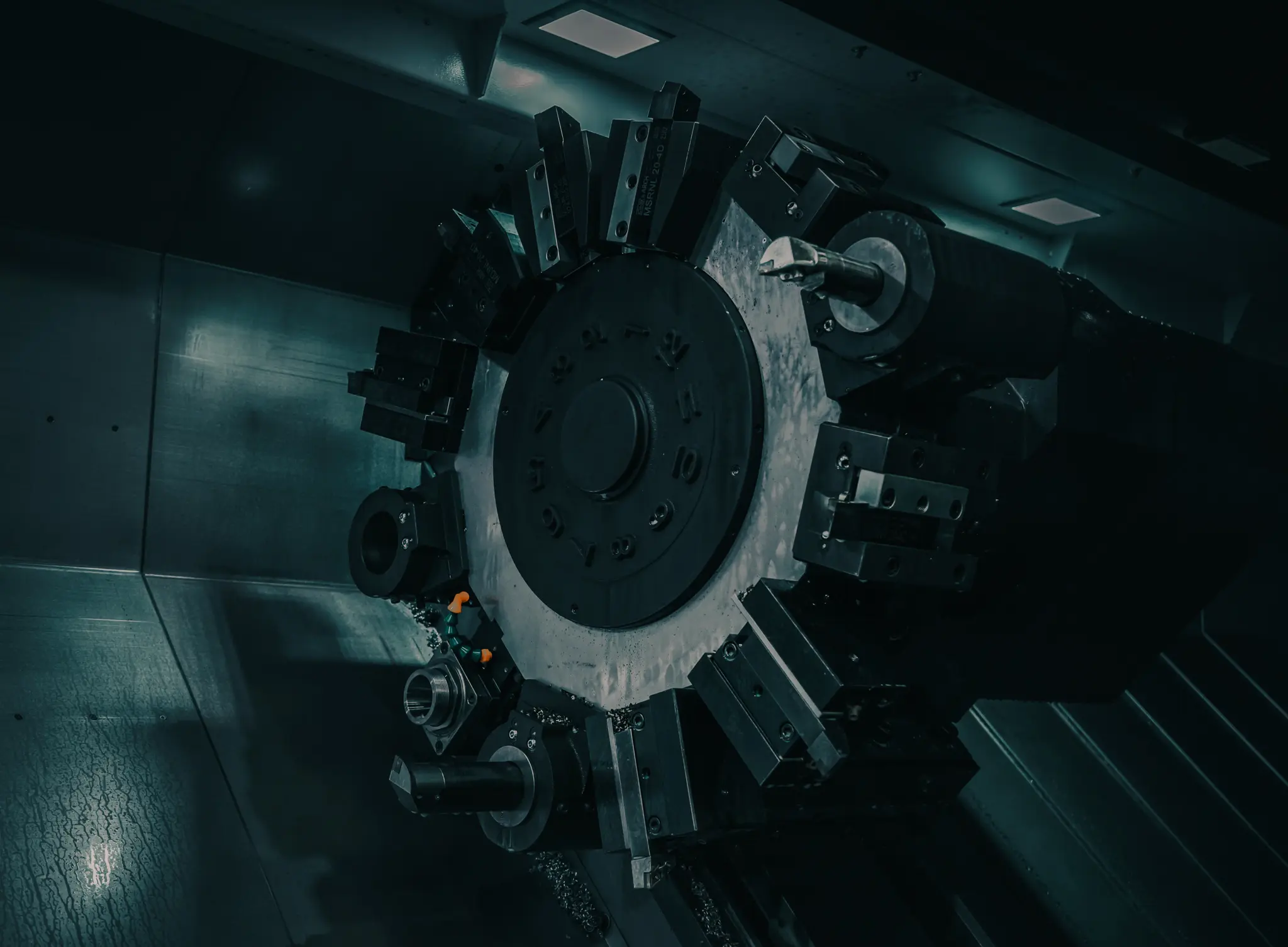

- CNC VERTICAL TURNING CENTERS - VTL

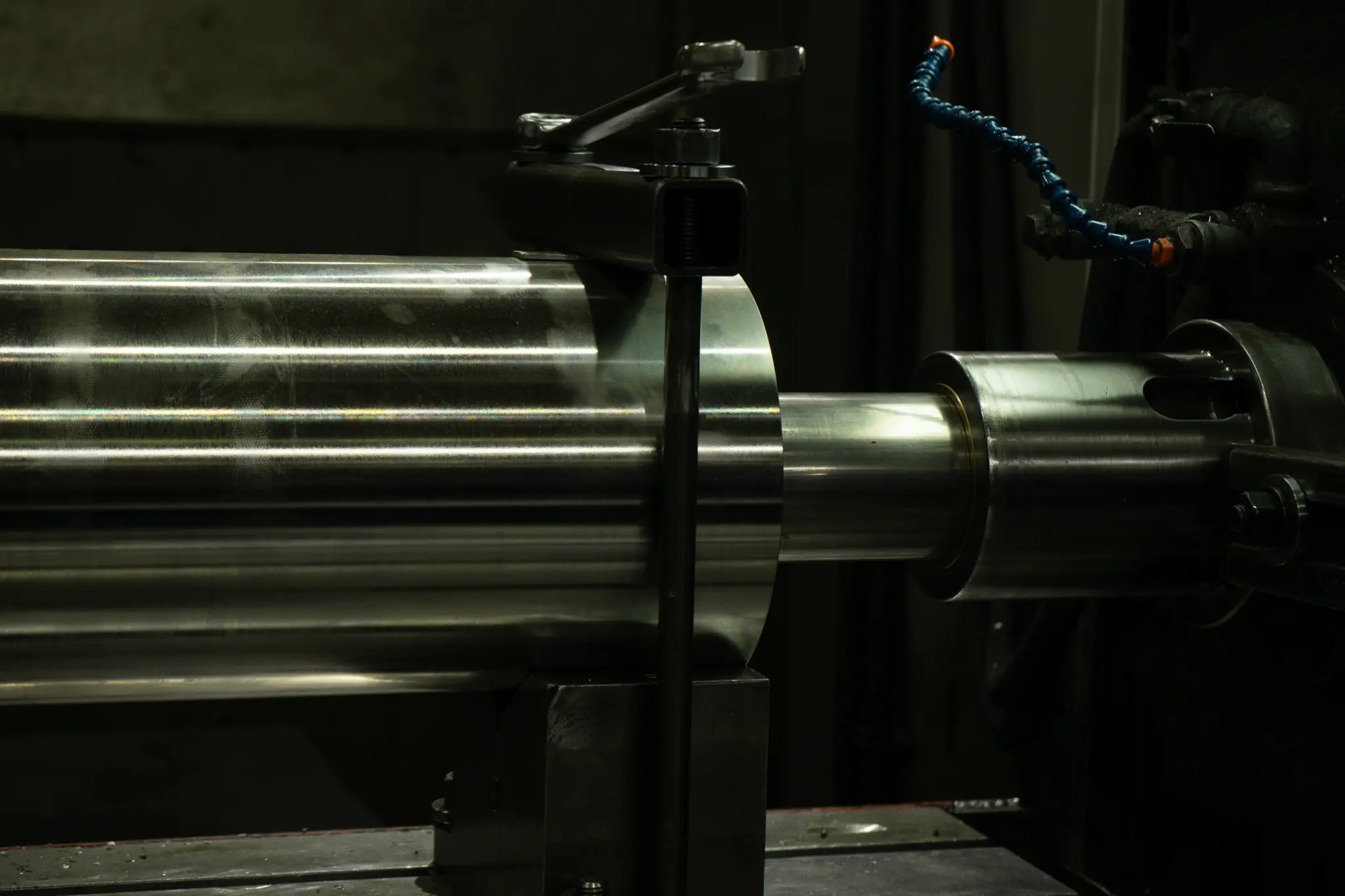

- CNC HORIZONTAL TURNING CENTERS

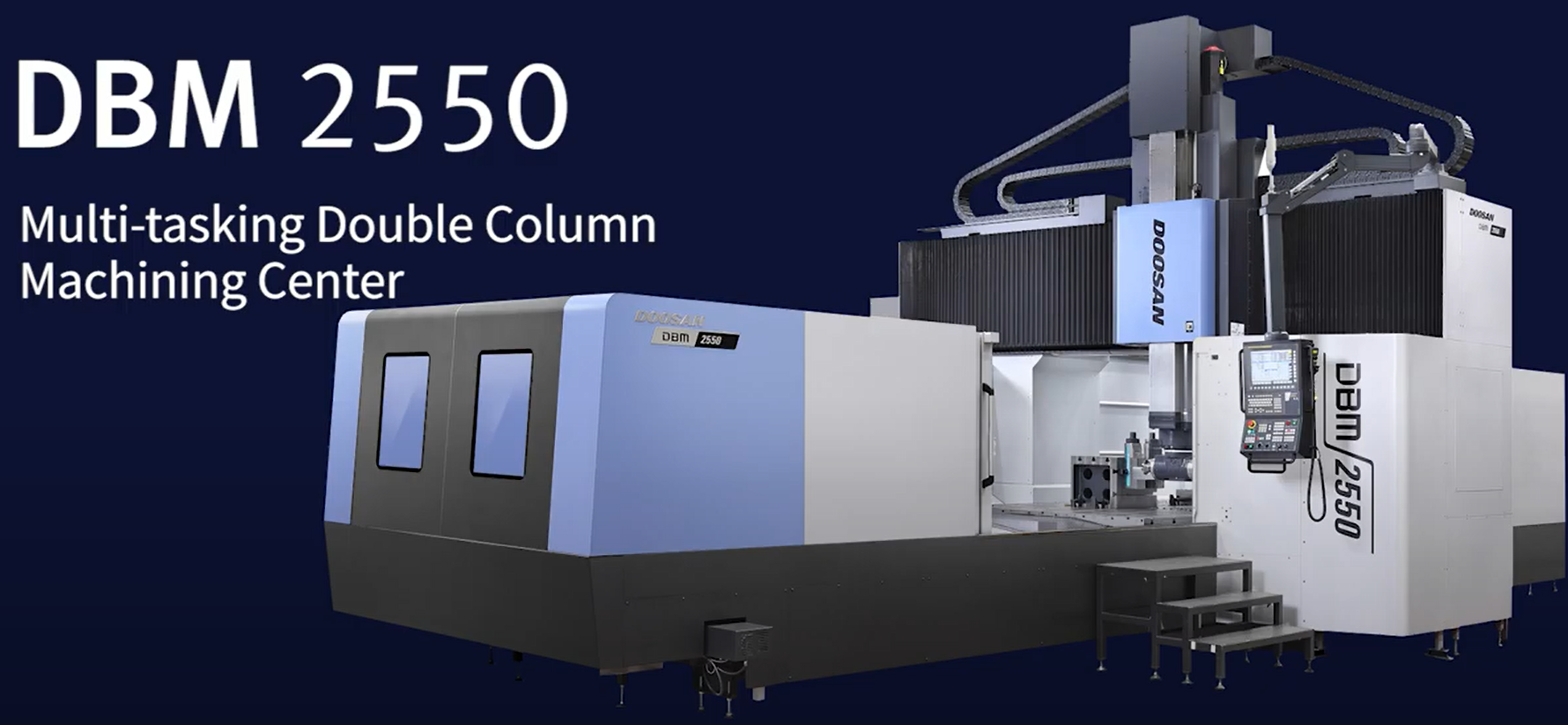

- CNC BRIDGE / GANTRY MILLS

- CNC BORING MILLS

- MANUAL BORING MILLS

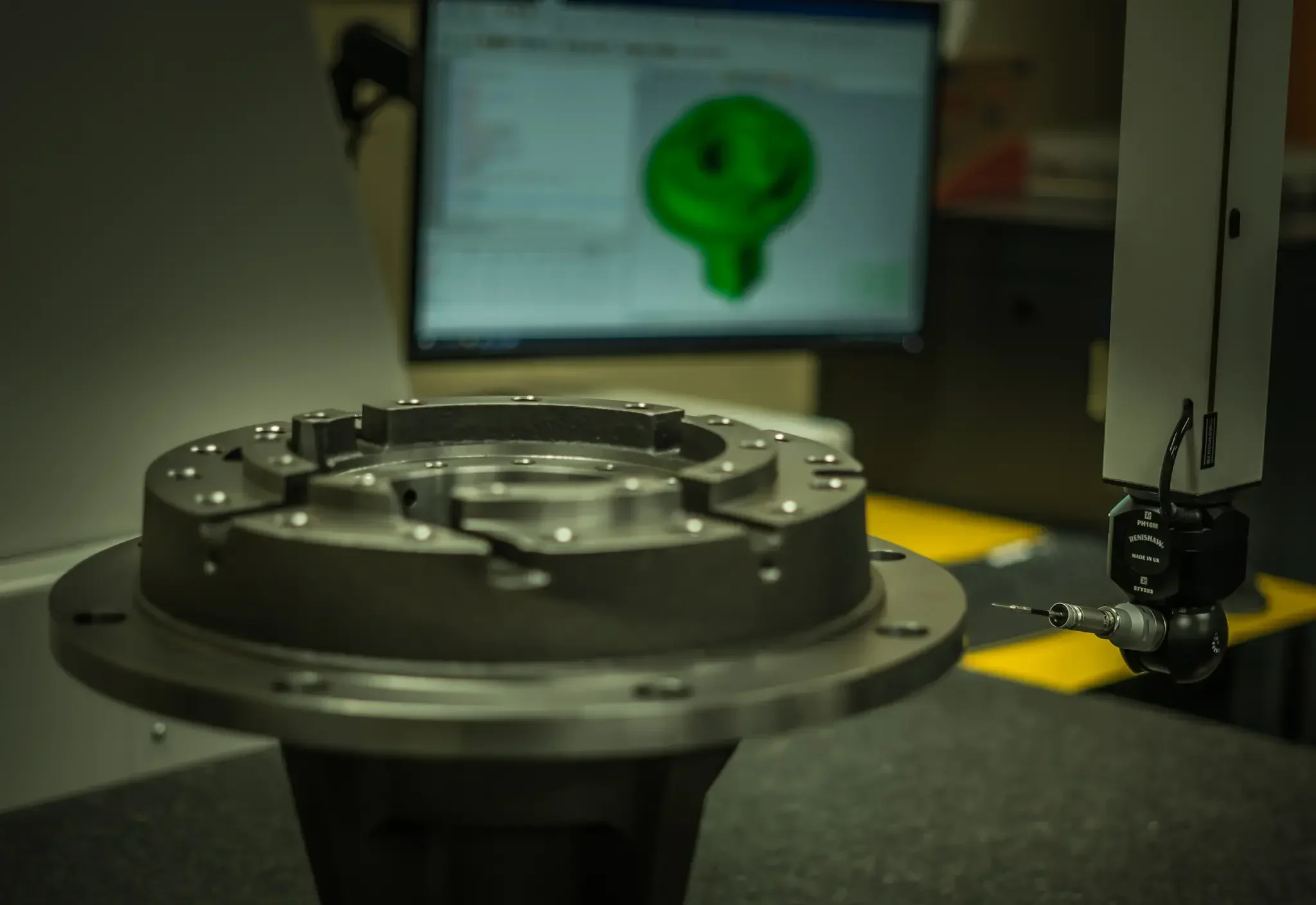

- QUALITY CONTROL EQUIPMENT

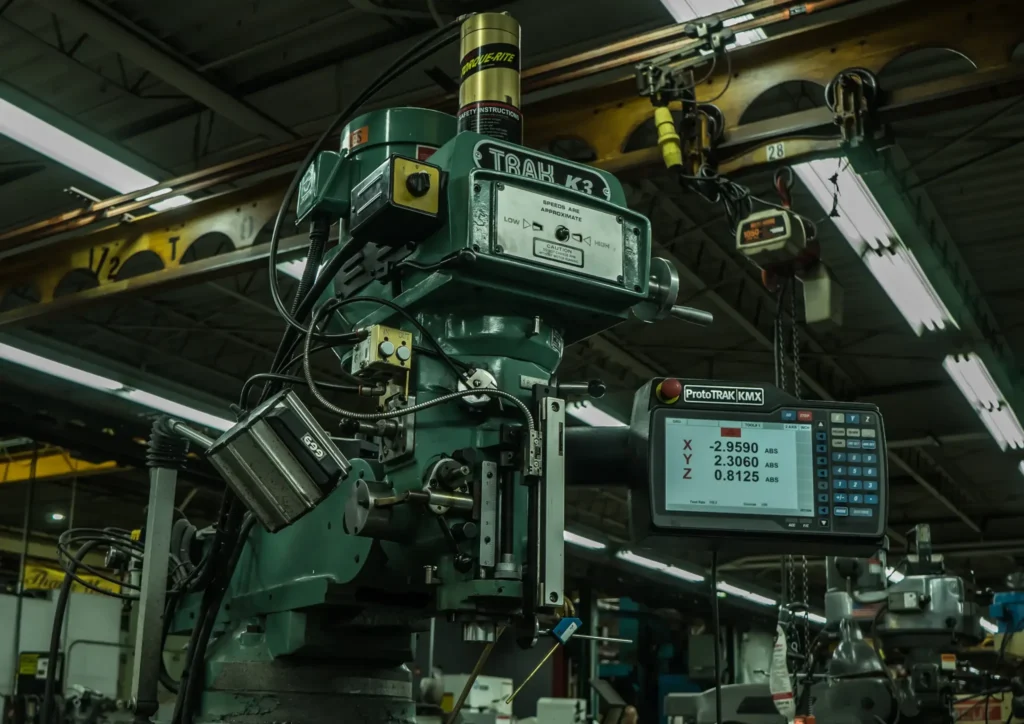

- MANUAL MILLS & LATHES

- ASSEMBLY, FABRICATION, PAINT & MORE

- GRINDERS

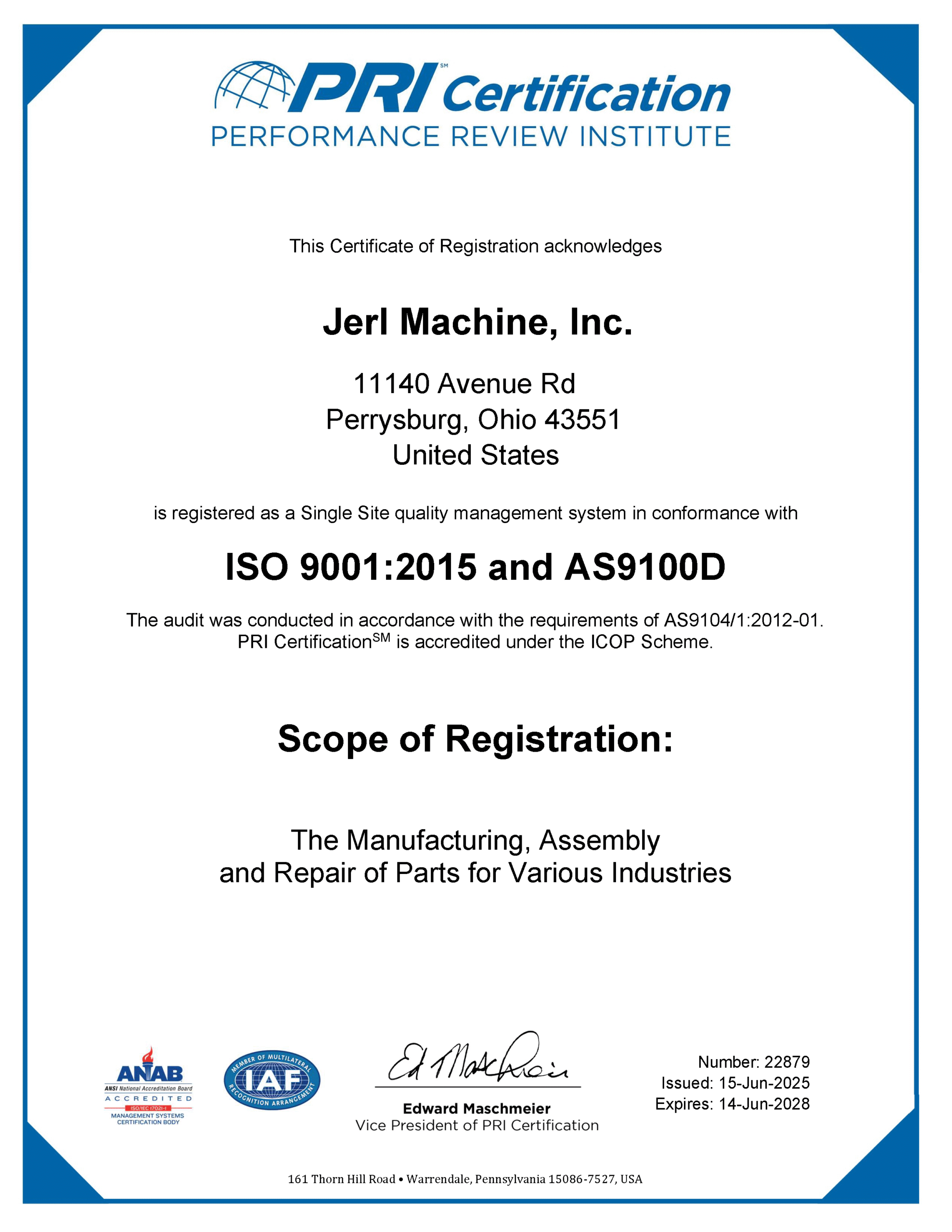

- CERTIFICATIONS & SOFTWARE

Key features of the Makino U6 EDM machine:

General Specs -- Metric -- English

X, Y Axis Travel -- 650mm x 450mm -- 25.59" x 17.71"

Z Axis Travel -- 420 mm -- 16.53"

Work Table Size -- 910mm x 710mm -- 35.8" x 28.0"

Maximum Load -- 1,500 kg -- 3,306 lbs.

Repeatability:

-X/Y-Axes (Full Stroke) ± 0.0015 mm -- ± 0.0001"

-Roundness TIR -- 0.005 mm -- 0.0003”

(7) Vertical Machining Centers with travel up to:

X= 43.00’’, Y=26.00’’, Z=24.00’’

16,000 RPM Max

Up to 2,700 lb. workload

CAT 40, 50, & BT-30

1000 PSI Thru-Spindle Coolant

Travels up to: X=206.00’’ Y=118.00’’ Z=43.3’’ (+300mm Riser)

360 degree right angle head (1 degree increments)

8,000 RPM

Cat 50

1000 PSI Thru-Spindle Coolant

Up to 48,400 lb. workload

Take a tour of our shop

Committed to excellence

Every step of the way